Packaging without Limits

MAX Solutions has the expertise, experience and technology to successfully deliver a wide range of innovative, specialty packaging solutions. From foil stamping to embossing and beyond, we create packaging with the highest impact and in the most sustainable way. Our next-generation assets and value-add services support a wide range of package applications for the high-end consumer brands, healthcare, media and industrial segments.

PRE-PRESS

G7 CERTIFICATION

Our printing crews and presses have undergone a rigorous testing and certification process in order to provide our customers with the highest standards of graphic production. With our Idealliance G7 Master Qualification for Superior Print Knowledge and Best Practices you can be sure that what you want is what you achieve with MAX Solutions.

CTP PRE-PRESS

No need to wait with CTP. Our computer-to-plate technology increases the speed of our workflow, reducing cost and improving production quality overall. Our full graphics pre-press service offers retouching, CF2 page layout and assists with your design specifications.

PRINTING

VERSATILITY, AGILITY & SPEED

Our next-generation technology will take your printing project to new heights and deliver consistent, eye-catching impact with speed and flexibility. Whether we leverage our custom-built, high definition press, our revolutionary extended gamut printing capabilities, our sophisticated layout optimization software or our hybrid label printing technology, the result is ALWAYS the highest quality product delivered to the market in the most efficient way. We have the ability to print offset, flexo and primographic on cartons, inserts, labels & rigid packaging.

MAX QUALITY

We take our commitment to delivering zero-defect quality to our customers seriously and have developed our exclusive MAX Quality program to ensure we deliver the best. All of our standard operating procedures have been developed in full compliance with ISO 9001:2015 Certification (expected Q3 2023/Q1 2024) and the FDA’s Current Good Manufacturing Practices (CGMP).

The investments we’ve made in technology support these efforts - in-press color control, in-line inspection, power registration and detection & ejection capabilities are a few of the advanced capabilities built into our equipment.

And to ensure the highest level of consistency in execution, we’ve invested in comprehensive quality management system (QISS) developed by the Quality Institute of America (QIA).

DIE-CUTTING

BLANKING

Ask us about the potential benefits of our blanking process in turning your projects around in rapid time. Using specialized tooling to convert printed sheets to foldable cartons without the need for a laborious hand stripping process, MAX Solutions’s blanking die-cutters can help your job to fly through the production process resulting in faster turn around times.

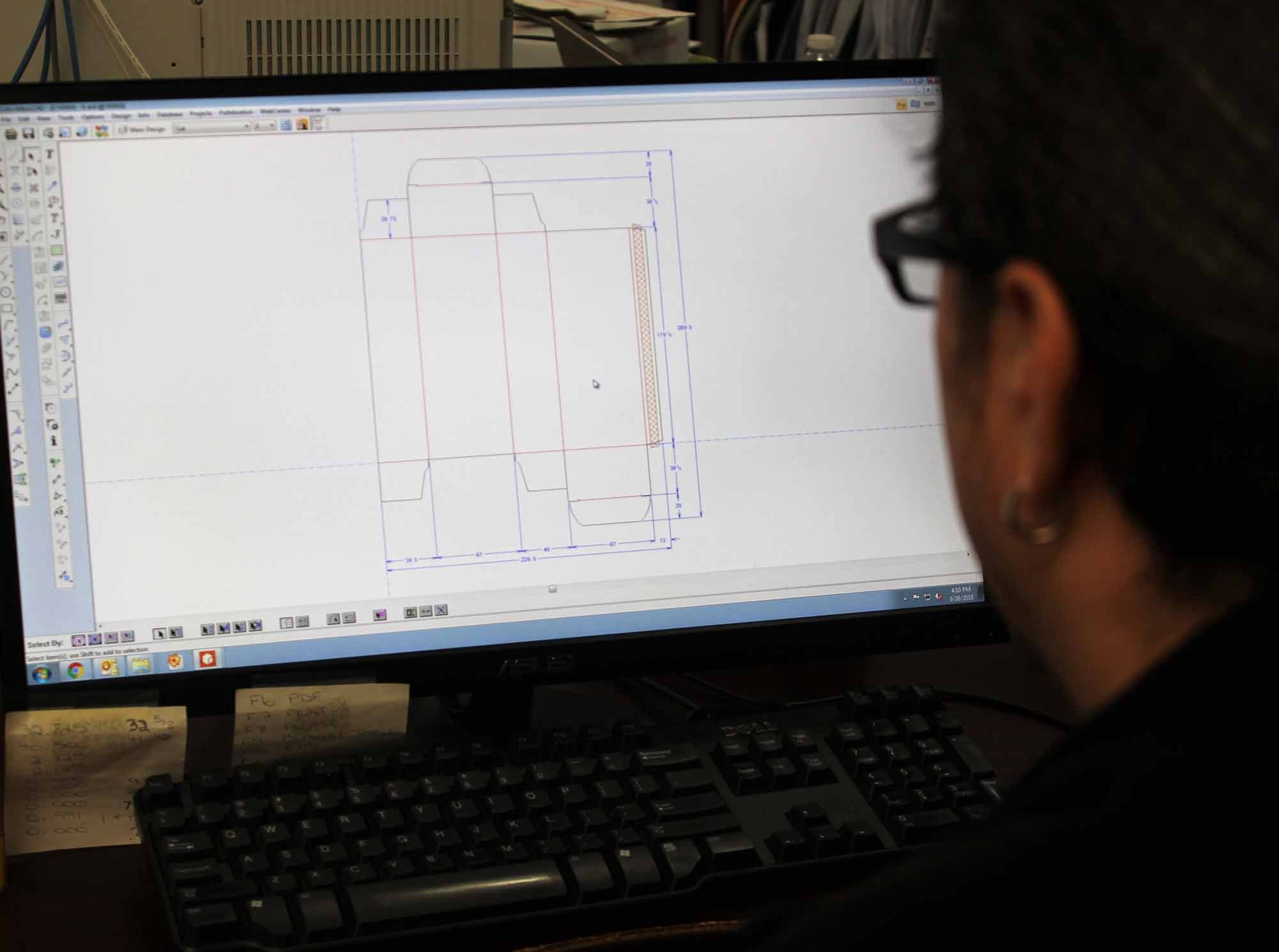

IN-HOUSE TOOLING

Allow us to take your ideas from concept to completion with our strategic use of in-house tooling. MAX Solutions manufactures and maintains its own die tooling with the use of sophisticated Gerber CAD/CAM technology. That’s how we’re able to work to an exceptionally high standard with shorter lead-times and the flexibility to adjust when required.

FINISHING

SPECIALTY EMBOSSING

Logos, graphics, and text elements are brought to life with our specialty embossing services. We can provide economically efficient in-line embossing or utilize a heated chase process combined with specially manufactured embossing plates to create a raised or depressed area on your package in any shape or design of your choice. We’ve even developed a unique process for Braille-embossed cartons to take your project to the next level.

IN-LINE BRAILLE EMBOSSING

With our in-line braille embossing equipped gluers MAX Solutions can add sophisticated and supremely accurate braille readable text to any carton project you bring to us. Ideally suited to the pharmaceutical and nutraceutical markets, adding braille at the gluing stage reduces cost and lead times to help bring your product to market quickly. Economically designed to use easily interchangeable embossing sleeves, our in-line application process is the perfect answer to your braille needs.

SPECIALTY COATINGS

Looking for something unique on your next packaging project? Our presses with advanced coating features offer Gloss, Satin, Soft Touch & Matte aqueous coatings along with pattern UV and HUV coatings specifically targeted for the demanding taint adverse chocolate confectionary market. Fully compatible with any number of our other custom printing effects such as embossing and foil stamping, our specialty coatings can create some truly amazing results.

HOLOGRAPHIC PRIMOGRAPHY

A stunning combination of foil roll application and holographic image printing, our holocoat service tied to our High Definition Flexo press is second to none in achieving a unique and premium look for your packaging project. With custom patterns and imagery available, the possibilities are endless. Contact our sales team today and ask to see a sample.

IN-LINE COLD FOIL APPLICATION

Applied during printing process, our in-line cold foil application service combines the eye-catching premium quality look of foil with affordability and efficiency. Couple cold foil with a custom chromatic ink and we can produce stunning effects in one pass, hot…or rather ‘cold’ off the press. Contact our sales team today and ask to see a sample.

HOT FOIL STAMPING

Available in a variety of metallic colors and patterns, hot foil stamping adds a touch of elegance to your project that’s unmatched by other techniques. Depending on the sophistication of the graphics, we can utilize economic magnesium dies, or for more complex projects, brass and copper dies to ensure even the finest details stand out while providing long lasting repeatability. Learn how to enhance your brand and make your printed materials brilliantly shine with one of our most exclusive finishing services.

CELLO WINDOWING

Need a folding carton with a transparent window that won’t compromise your product’s integrity? Our multi-lane windowing equipment can apply any special shape, size, or thickness of cello window to your carton – even to chipboard or N-Flute substrates. When actually seeing your product can enhance its sales, our creative team can design a windowed carton that can truly be the perfect showcase.

SECURITY TAG LABELLING

If your product needs security in the retail space, MAX Solutions has you covered with our security tag label application services. We can affix multiple varieties of security tag labels to your cartons in custom ratios and sequences allowing you to maximize your security needs. Ask our sales team today about our security tagging options.

CUTTING EDGE APPLICATION

Looking to add a serrated cutting edge to your wax or parchment paper carton? Look no further than MAX Solutions. In addition to providing all the printing and converting services you’ll need, we have in-house equipment ready to apply premium add-on cutting edge strips to your cartons.

INK-JET CODING

If you’re in need of unique printed codes applied to your cartons, whether it’s for production line tracking or for secure promotional contests, MAX Solutions is ready. Our rapid print application ink-jet system from Videojet can add unique, sequential, or randomized alphanumeric codes to any project.

SPECIALTY TRAY FORMING

Serving the needs of the agricultural produce and fast-food restaurant industries, MAX Solutions has your specialty tray needs met. With most major grocery retailers now demanding that produce be packaged for branding, sustainability, hygienic and handling efficiencies, we have responded with clamshells and tray forming solutions, efficiently manufactured on our exclusive custom machinery, in smaller volumes, often avoiding expensive proprietary tooling. Check out why tray forming is now among our fastest growing market segments.